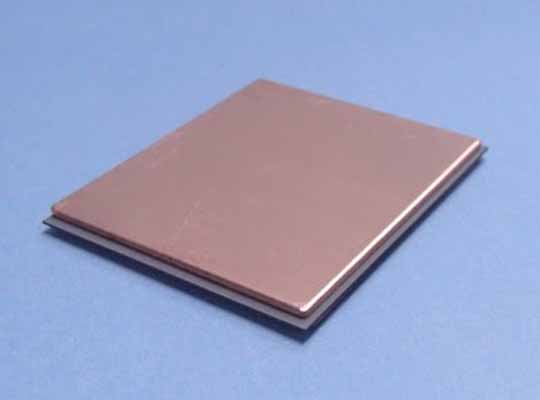

TOKYO, TANAKA Holdings Co., Ltd. (Head office: Chiyoda-ku, Tokyo; Representative Director & CEO: Koichiro Tanaka) reported today that TANAKA Kikinzoku Kogyo K.K. (Head office: Chiyoda-ku, Tokyo; Representative Director & CEO: Koichiro Tanaka), which operates the TANAKA Precious Metals manufacturing business, developed an active brazing filler metal/copper composite material for power devices that can reduce processing times.

The new product is a composite (cladding) of copper (Cu) material with active brazing filler metal on one side. Since it can be joined directly to any material including ceramics (oxides, nitrides, and carbides) and carbon materials, it is expected that it will be used in ceramic substrates and next-generation heat sinks for power devices. In addition, TANAKA can make various proposals tailored to customer needs fluctuating from supply of prototypes using this product to brazing1 processes, testing, and evaluation.

Product Features and New Processing Proposals: Both High Heat Dissipation and Processing Labor Savings Possible

Improved Performance

- The thick Cu electrodes needed for high heat dissipation heat sinks can be formed Directly on ceramics, which was difficult to do with existing etching2 processes. This makes possible even finer wiring pitch.

- Since the material does not contain any solvents, there is no residue and bonding reliability is improved.

Cost Reduction

- The brazing filler thickness can be 10 μm (micrometers) or less, which means that compared to earlier active brazing filler metal, silver bullion costs can be reduced by half or more and the brazing filler thermal resistance is halved.

- The Cu material is compounded, which means that a pattern can be formed simply by setting the material, reducing processing costs.

Environmental Impact Reduction

- Since the material contains no solvents, volatile organic compounds (VOCs) are not released.

In addition, the brazing time can be greatly reduced, which leads to energy savings and can be expected to reduce environmental impact.

As a result of the features described above, this product can be used in a wide range of semiconductor applications, with expectations particularly high for deployment in the heat dissipation field.

Potential for Contributions by this Product in Individual Heat Dissipation Areas

In the power devices market, higher outputs and increased efficiency are demanded, and in conjunction with this, heat generation is rising. As a result, providing individual components with high heat dissipation, high heat resistance, and high bonding reliability and developing materials that are compatible with even further miniaturization are urgent priorities for the industry. This is especially the case in the market for eco-cars such as electric vehicles (EVs) and hybrid vehicles (HVs), the high-output laser diode market, and the market for next-generation heat sinks,3 demand for which in the PC, smartphone, and other markets is expected to grow. To maintain high heat dissipation, high heat resistance, and high bonding reliability, it is first necessary to increase the thickness of the Cu plate, and this product make it possible to form electrodes on a thick Cu material and enhances bonding reliability without using etching, so it can be expected to contribute to higher heat dissipation.

TANAKA plans to begin full-scale sample shipments in 2021 and establish a mass production system in 2023

Going forward, TANAKA will continue to develop products tailored to customer needs and to develop technologies with an eye towards expanding its lineup of active brazing filler metals.

1 Brazing A method of joining metals or other materials whereby an alloy (brazing filler metal) with a melting point lower than the base materials to be joined is melted and the base material is melted as little as possible.

2 Etching Also referred to as chemical corrosion. Etching is used a process for obtaining the desired shape by dissolving and eroding unneeded areas.

3 Heat sink A component of machinery that is intended to dissipate and absorb heat. Heat sinks are often made of metals with good heat conduction properties such as aluminum, iron, or copper, but graphite is also attracting attention for next-generation heat sinks. Applications include cooling semiconductor components, coolers in refrigerators and air conditioners, and radiators and heaters in automobiles.

TANAKA’s Active Brazing Filler Metals

The active brazing filler metals used are updated versions of earlier products and are silver (Ag), copper (Cu), tin (Sn), and titanium (Ti) allows that can be used to braze ceramics. AgCuSnTi alloys can be dispersed more finely than SnTi alloys and support manufacturing and supply of product with thin brazing filler.