Not to get confused between photovoltaic (PV) cell and solar cell as both states the same potential. As when a light strikes on photovoltaic (PV) cell, it moves through the cell by the procedure of absorbing, reflecting and powering up the cell to generate electricity.

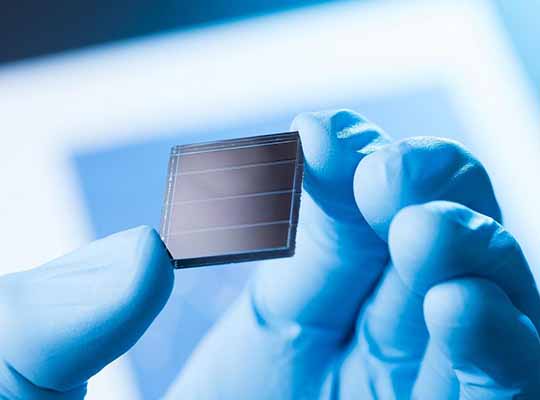

A PV cell or solar cell is composed with semiconductor material which helps in conductivity of electricity, there are several different semiconductor materials used in PV cells.

When the semiconductor is exposed to light, it absorbs the light’s energy and transfers it to negatively charged particles in the material called electrons. This extra energy allows the electrons to flow through the material as an electrical current. This current is extracted through conductive metal contacts – the grid-like lines on a solar cells – and can then be used to power your home and the rest of the electric grid. The efficiency of a PV cell is simply the amount of electrical power coming out of the cell compared to the energy from the light shining on it, which indicates how effective the cell is at converting energy from one form to the other. The amount of electricity produced from PV cells depends on the characteristics (such as intensity and wavelengths) of the light available and multiple performance attributes of the cell.

Silicon

Silicon is, by far, the most common semiconductor material used in solar cells, representing approximately 95% of the modules sold today. It is also the second most abundant material on Earth (after oxygen) and the most common semiconductor used in computer chips. Crystalline silicon cells are made of silicon atoms connected to one another to form a crystal lattice. This lattice provides an organized structure that makes conversion of light into electricity more efficient.

Solar cells made out of silicon currently provide a combination of high efficiency, low cost, and long lifetime. Modules are expected to last for 25 years or more, still producing more than 80% of their original power after this time.

Thin-Film Photovoltaics

A thin-film solar cell is made by depositing one or more thin layers of PV material on a supporting material such as glass, plastic, or metal. There are two main types of thin-film PV semiconductors on the market today: cadmium telluride (CdTe) and copper indium gallium diselenide (CIGS). Both materials can be deposited directly onto either the front or back of the module surface.

CdTe is the second-most common PV material after silicon, and CdTe cells can be made using low-cost manufacturing processes. While this makes them a cost-effective alternative, their efficiencies still aren’t quite as high as silicon. CIGS cells have optimal properties for a PV material and high efficiencies in the lab, but the complexity involved in combining four elements makes the transition from lab to manufacturing more challenging. Both CdTe and CIGS require more protection than silicon to enable long-lasting operation outdoors.

Perovskite Photovoltaics

Perovskite solar cells are a type of thin-film cell and are named after their characteristic crystal structure. Perovskite cells are built with layers of materials that are printed, coated, or vacuum-deposited onto an underlying support layer, known as the substrate. They are typically easy to assemble and can reach efficiencies similar to crystalline silicon. In the lab, perovskite solar cell efficiencies have improved faster than any other PV material, from 3% in 2009 to over 25% in 2020. To be commercially viable, perovskite PV cells have to become stable enough to survive 20 years outdoors, so researchers are working on making them more durable and developing large-scale, low-cost manufacturing techniques.

Organic Photovoltaics

Organic PV, or OPV, cells are composed of carbon-rich (organic) compounds and can be tailored to enhance a specific function of the PV cell, such as bandgap, transparency, or color. OPV cells are currently only about half as efficient as crystalline silicon cells and have shorter operating lifetimes, but could be less expensive to manufacture in high volumes. They can also be applied to a variety of supporting materials, such as flexible plastic, making OPV able to serve a wide variety of uses.PV

Concentration Photovoltaics

Concentration PV, also known as CPV, focuses sunlight onto a solar cell by using a mirror or lens. By focusing sunlight onto a small area, less PV material is required. PV materials become more efficient as the light becomes more concentrated, so the highest overall efficiencies are obtained with CPV cells and modules. However, more expensive materials, manufacturing techniques, and ability to track the movement of the sun are required, so demonstrating the necessary cost advantage over today’s high-volume silicon modules has become challenging.

Advances in Solar Panel Technology

- Solar Powered Automobiles

Currently, the transportation sector is a leading contributor to greenhouse gas emissions. While many countries are leveraging purely electric vehicles that are recharged from renewable energy from the grid, some countries do not have access to renewable grid energy. Moreover, in many regions, accessibility to the grid is limited to those in urban areas. As such, solar powered automobiles provide an opportunity to move away from fossil fuels for these people.

- Solar Roads

Solar roads are solar panels that are installed in roadways. They are designed to be strong enough to overcome large amounts of pressure and should be capable of generating significant amounts of solar energy, even when covered by other materials. The purpose of solar roads is to provide energy to vehicles so that they can be driven without extensive fuel usage. The installation of solar roads became a popular idea once near to efficacy (expected) results were yielded from a French trial. The trial showcased that 2800 m2 of road covered with solar panels could yield 420 kWh per day but at a price of $14,000 per kilowatt (The average installation costs for solar panels on homes is $3140).

- Solar Paint

Solar paint can capture energy from the Sun and convert it into electricity. The advantages associated with these paints revolves around the wide range of applications, but they currently lack the efficiency of traditional solar panels. Despite this, solar paints are likely to be commercialized within the next five years [9]. There are three types of solar paints: hydrogen-extracting solar paint (solar paint hydrogens), quantum dot solar cells (photovoltaic paint), and perovskite solar paint, which can all be applied in a variety of situations.

- Solar Glass

Solar glass along with solar windows, are transparent solar cells that can transform the way solar energy is collected and harnessed. They can turn sunlight into energy without needing the bluish-grey opaque panels, where electricity is generated from, and can be harnessed on any glass surface. Solar glass is regular glass that has a coating of an organic dye on its surface which allows visible light to pass through and invisible infrared rays to be collected, captured, and then converted into electricity.

Solar Panel Technologies Set To Change the Solar Sector

- Floating solar farms (aka ‘floatovoltaics’)

Silicon panels are becoming cheaper and more efficient day-by-day. According to experts, if photovoltaic panels are placed on reservoirs and other water bodies, they offer even greater efficiency as well as a plethora of other benefits.

“Floatovoltaics” are photovoltaic solar power systems created for floating on reservoirs, dams, and other water bodies.

- BIPV solar technology

Building-integrated photovoltaics, as the name suggests, seamlessly blend into building architecture in the form of roofs, canopies, curtain walls, facades, and skylight systems. Unlike traditional solar PV panels, BIPV can be aesthetically appealing rather than a compromise to a building’s design.

Of course, aesthetics alone is not enough for solar buyers; economics matters too. The good news is that the BIPV solar panel systems enable homeowners to save on building materials and electric power costs. By substituting BIPV for standard building materials, you can cut down on the additional cost of solar panel mounting systems.

- Solar fabric

Solar radiation is available all over the planet, so why not generate your own energy, wherever required? Imagine that besides producing solar power at a fixed location, you could also do it while on the move through your own clothing.

Researchers are developing solar fabrics with a vision of including solar power in each fiber. These solar filaments can be embedded into your t-shirts, winter coats, or any other clothing to help you keep warmer, power your phone, and provide energy for other needs while you’re on the go.

The recent innovation of solar-powered cars showcases a prominent application of solar energy technology. These vehicles are capable of harnessing solar energy through solar cells and can more efficiency use the energy for motion, compared to traditional gas-powered automobiles. In addition, the advent of solar skins introduces levels of cosmetic customization to vehicles, while incorporating solar energy technology at economically feasible costs. Advancements in calcium titanium oxide will likely further increase the efficiency of solar panels and widen the range of solar applications in the future.

Meanwhile, solar roads are now being made in major countries like America, China, and Japan, to generate energy for on-road vehicles. Hydrogen-extracting solar paints, quantum dot solar cells, and perovskite solar paints can serve as primary energy sources for buildings and may revolutionize the energy industry.