The Low Density Polyethylene Market is witnessing a significant surge in demand across multiple sectors. From flexible packaging to agriculture and construction, LDPE is emerging as a versatile material that aligns with industry requirements for lightweight, durable, and cost-effective solutions. As industries pivot towards innovation, sustainability, and consumer-centric packaging, LDPE is carving a stronger presence across global supply chains.

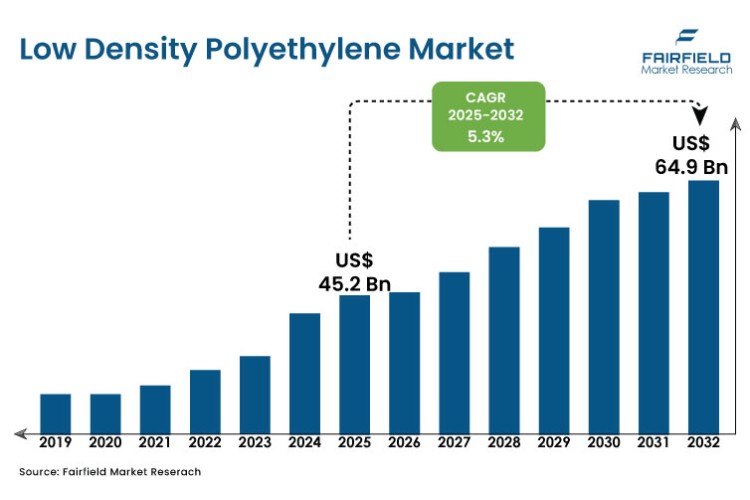

According to analysts at Fairfield Market Research, this market is expected to experience consistent growth due to the increasing need for flexible, eco-conscious, and recyclable plastic solutions. In this blog, we explore the top five growth opportunities in the Low Density Polyethylene Market that are expected to reshape its trajectory in the coming years.

1. Booming Demand in Flexible and Sustainable Packaging

One of the most compelling opportunities driving the Low Density Polyethylene Market is the rapid evolution in the packaging industry. As consumer awareness around sustainability grows, companies are actively seeking flexible packaging solutions that reduce material usage while maintaining product integrity. LDPE fits the bill perfectly.

Flexible packaging made from LDPE is lightweight, cost-efficient, and offers excellent moisture resistance. It’s used in grocery bags, milk cartons, frozen food, and stretch films. Moreover, manufacturers are innovating with thinner LDPE films to cut down on plastic use without compromising strength. This shift toward eco-friendly and recyclable packaging is accelerating LDPE adoption across both developed and emerging economies.

The global e-commerce boom is also contributing to this trend. The increasing need for robust packaging solutions for online deliveries is pushing retailers to opt for LDPE-based protective films and bubble wraps, further strengthening market demand.

2. Expanding Agricultural Film Applications

Agriculture is undergoing a transformation driven by technology, climate adaptation, and the need for higher crop yield. LDPE-based agricultural films are becoming indispensable in this transition. Mulch films, greenhouse films, and silage films made from LDPE are helping farmers improve productivity by regulating soil temperature, conserving moisture, and minimizing weed growth.

The increasing adoption of smart farming practices in countries like India, China, and Brazil is leading to significant investments in high-performance agricultural films. These films are not only cost-effective but also recyclable, which fits well with the global push toward sustainable agricultural practices.

In addition, government subsidies in several regions for promoting advanced farming materials are positively influencing LDPE film adoption. As the global population grows and arable land shrinks, this sector will play a key role in boosting demand for LDPE.

3. Rising Use in the Construction and Infrastructure Sector

Another fast-expanding application area is the construction industry. LDPE’s lightweight, chemical-resistant, and flexible characteristics make it suitable for a wide range of building materials including vapor barriers, insulation films, and protective sheeting.

With rising infrastructure development in emerging markets across Asia, Africa, and Latin America, the need for cost-efficient and durable materials is growing. LDPE is being increasingly used in water-proof membranes, damp-proof courses, and underlayment for roofing and flooring. These applications help improve energy efficiency and prolong the lifespan of buildings.

As governments continue to fund large-scale public infrastructure and affordable housing programs, the Low Density Polyethylene Market is poised to benefit significantly from the construction sector’s expansion.

4. Emerging Role in Medical and Healthcare Applications

The global healthcare sector is rapidly modernizing, and with that comes increased demand for hygienic, flexible, and sterile materials. LDPE is finding new ground in this sector thanks to its non-toxic nature, flexibility, and excellent moisture barrier properties.

LDPE is used in the manufacturing of medical bottles, intravenous (IV) bags, disposable gloves, syringes, and tubing. It’s also a common choice for packaging pharmaceutical products due to its protective capabilities against contamination. As healthcare infrastructure expands in developing regions and aging populations demand more healthcare products, this sector presents a massive opportunity for LDPE manufacturers.

In the post-pandemic world, hygiene and single-use medical products have become even more critical, bolstering the demand for LDPE in hospitals and clinics. Innovations in medical-grade LDPE further support its use in sensitive environments where safety and flexibility are non-negotiable.

5. Technological Advancements and Circular Economy Integration

Technological innovation is paving the way for next-generation LDPE products that are not just efficient but also sustainable. With increasing pressure to reduce plastic waste, companies are investing in the development of bio-based LDPE, advanced recycling technologies, and multi-layer LDPE films that enhance durability and recyclability.

One key area of innovation is chemical recycling, where LDPE waste can be broken down and repurposed without losing material quality. This supports the circular economy model that many global brands are striving for. Also, the shift towards green manufacturing processes—such as using renewable feedstock for LDPE production—is likely to become a major differentiator in the future.

Major players are collaborating with governments, NGOs, and research institutions to implement closed-loop systems that recover and reuse LDPE from industrial and consumer waste. These innovations not only address regulatory concerns but also present cost advantages for businesses.

The Low Density Polyethylene Market stands at the crossroads of innovation, sustainability, and industrial expansion. As highlighted by Fairfield Market Research, the material’s diverse application across industries makes it a high-potential segment for investors, manufacturers, and policymakers alike. From flexible packaging and agriculture to construction and healthcare, LDPE is proving to be more than just a basic plastic—it’s a future-ready material with vast possibilities.

The top five opportunities discussed—flexible packaging, agricultural films, construction use, medical applications, and technological innovations—collectively underscore a robust future for LDPE. Businesses that can align with these trends are likely to stay ahead in a competitive, regulation-conscious world.

As environmental concerns and end-user expectations continue to evolve, the LDPE market’s adaptability will be its greatest strength. Staying informed and investing in innovation will be crucial for stakeholders seeking long-term value from this dynamic sector.