StoreDot has obtained outstanding battery performance feedback for the first evaluation and integration A-Samples testing phase of its XFC electric vehicle battery cells.

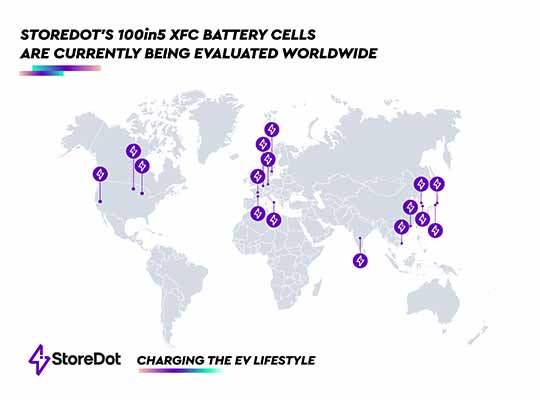

The comprehensive testing programs took place over the past six months by 15 leading global automotive brand manufacturers from Europe, Asia, and the US, as well as several of StoreDot’s strategic ecosystem partners. Feedback from partners that have completed tests showed that the cells exceeded expectations, with those still conducting tests expected to report similar results.

The aim of the testing and evaluation programs was predominantly to replicate StoreDot’s unique extreme fast charging specifications based on its partners’ use case and test procedures. When the OEMs and partners replicated StoreDot’s results, they reached an energy density greater than 300Wh/kg, at a charging rate higher than 4C, achieving over 1000 consecutive XFC charging cycles.

The programs encompassed two main paths: The first included XFC datasheet and specification verification based on StoreDot’s rigorous testing procedures, and the second covered specific EV-OEM test protocols for critical performance and safety parameters relevant to their use cases.

The feedback received was overwhelmingly positive, surpassing StoreDot’s target specifications. Some OEM partners have already progressed to phase two of the testing programs, which involves the initiation of B-Samples programs tailored to their own form-factor and specific requirements, enabling future implementation in each OEM EV architecture.

Amir Tirosh, StoreDot COO “We are hugely confident in our XFC technology – the ability to charge the cell from 10%-80% in just 10 minutes – based on our own rigorous testing procedures. However, receiving such positive feedback from global EV manufacturers gives us even more assurance in our groundbreaking product. Our partners are extremely pleased with the results of our battery cells, showcasing unprecedented energy density levels, and charging times that will prove to be a game-changer for the entire industry. The testing results confirm the value proposition that XFC is critical in eliminating range and charging anxiety, while at the same time empowering OEMs to design EVs with smaller pack sizes that can charge in minutes. Using standard Li-ion manufacturing lines either owned by the partners themselves or with subcontractors, this success enables us to promptly begin selective collaboration on B-samples with our partners.”

StoreDot continues to foster a growing network of strategic global partnerships and investors, encompassing the entire battery ecosystem. Notably, it has received investments from renowned global automotive manufacturers such as Daimler, Ola Electric, Polestar, VinFast, and Volvo Cars.

Last year, StoreDot unveiled its ambitious ‘100inX’ strategic technology roadmap, outlining three generations of StoreDot technologies: Silicon dominant XFC, semi-solid state, and post-lithium architecture. This roadmap reiterates that the anticipated milestones will be delivered over the next decade, with 100in5 targeted for 2024, 100in3 for 2028, and 100in2 for 2032.