KOHLER, Wis. – KOHLER Power is pleased to introduce the KOHLER eFRAME industrial generator enclosures that exceed the stringent expectations of mission critical applications – namely data centers – including shortened lead times, ease of installation, service and maintenance.

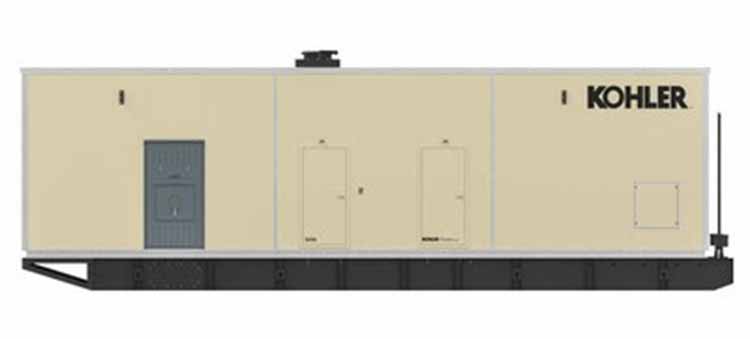

The eFRAME walk-in enclosure houses the KOHLER KD Series of industrial generators at 2000kw and up, and is available in three configurations – V12 (2000kW-2500kW), V16 (2800kW-3250kW) and V20 (3500kW-4000kW). It is highly durable and features an all-aluminum skin and frame construction, a fade/scratch/corrosion-resistant powdered coat exterior, and is designed to meet or exceed 135-mph wind load rating.

Additionally, the entire power system is a totally integrated package, with all components single-sourced from the Kohler factory including engineering, manufacturing and testing.

“The eFRAME walk-in enclosure is ideal for mission critical applications – including data centers, water utility, and healthcare – and can be customizable to meet the needs of our customers,” said Brad Meissner, product manager for KOHLER Power. “We’re the only manufacturer to ensure that the complete design, production, and testing occurs right at our factory. The one-stop approach increases our control of the entire manufacturing and testing process to ensure the highest quality while significantly decreasing lead times, which is very important for data center customers that operate under tight timelines.”

The KOHLER eFRAME enclosure features a unique modular enclosure design that provides the ultimate in serviceability, allowing users the ability to service the engine and radiator without disconnecting any site connections that occur in the rearward section of the enclosure.

With the enclosure capable of being separated into three sections, one section can be independently removed in the field if a major generator set component replacement is required. This localizes the service work to avoid potential mishaps to other components while significantly reducing service costs and downtime.

Installing the enclosed generator set consists of five simple steps that save time. First, the sub-base fuel tank is set in place, followed by mounting the generator set directly to the tank, and then setting the enclosure atop of the generator. Next is wiring the alternator load leads to the free standing breaker, and then completing customer connections, including load leads, shore power, and communication cables.

The durable enclosure has gone through vigorous testing and approval to ensure reliability. In addition to the wind rating, it is also UL2200 FTTP certified for construction and IBC certified via analysis for site specific use. The subbase tanks meet UL 142, ULC, and state specific requirements. Computational Fluid Dynamic (CFD) tools review the enclosure airflow to ensure generators will operate efficiently in the most demanding environments. The KOHLER eFRAME enclosures will be available in late summer.

Plant expansion addresses single-source capability for large generators

In early March, Kohler Power initiated a 155,000 square-foot expansion to its existing manufacturing facility in Mosel, Wisconsin. The project will include a state-of-the-art production and testing space of large generators above 2,000 kilowatts, switchgear, and engineered enclosures – including the new eFRAME enclosure. The project also delivers the needed space to enhance Kohler’s vendor managed finished goods stocking program, which is essential for key partners in the data center market. Finally, a world-class customer experience center will showcase Kohler’s proud 101-year history of power, and offer existing and future customers a comfortable environment and gracious experience while on-site.