BOSTON- Thermal interface materials (TIMs) are a key component in a multitude of electronic and energy storage devices. Essentially, if heat is generated and needs to be transferred (e.g. to a heat sink) then a TIM is typically needed. The form and composition of TIMs vary greatly across applications and markets with most large material suppliers also manufacturing TIMs. There are several industries that are starting to emerge and/or focus more on thermal management and the requirement for TIMs, leading to new and extremely large potential markets.

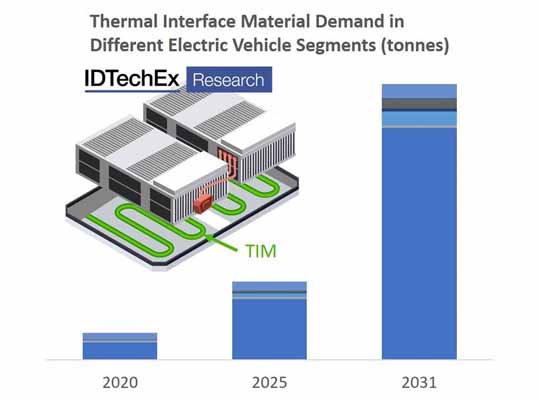

It is without a doubt that electric vehicles (EVs) are the future of transportation. The EV market continued its growth in 2020 despite the impact of COVID-19 on the automotive industry as a whole. Not only is the EV market set to grow rapidly over the next 10 years, but within this, there is a trend towards higher energy density, faster charging, longer lifetimes, and fire safety, all of which require effective thermal management and materials to support this. There is no consensus on battery design for EVs with a variety of cell formats, thermal management strategies, and pack designs, each of which influences the TIM quantity and utilization. IDTechEx has extensive research into the design of EV batteries with a comprehensive model database covering the market shares of different cell formats, energy densities, and much more. In their new research report, “Thermal Interface Materials 2021-2031: Technologies, Markets and Opportunities”, IDTechEx cover the demand for EV batteries across multiple vehicle segments (cars, buses, trucks, vans, two-wheelers, and more), automotive teardowns of TIM utilization, analysis of trends and drivers towards specific TIM formats.

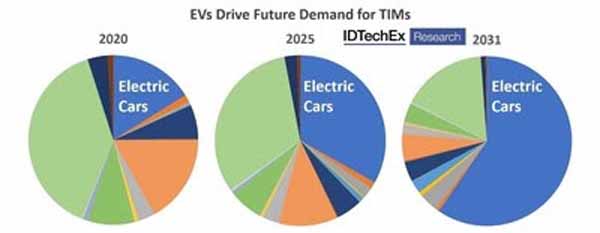

Of the categories studied, EVs create the largest demand for TIMs in 2031. Source: IDTechEx report, “Thermal Interface Materials 2021-2031: Technologies, Markets and Opportunities”.

Many manufacturers including Tesla, BYD, and VW have stated their intentions to move away from having multiple modules in a pack and, instead, having cell-to-pack options. This removes or reduces the need for a lot of the materials in a battery pack such as module housings, coolant lines and module interconnects. Whilst we may see several components eliminated, TIMs are still a requirement as moving heat from the cells to the thermal management system will always be needed in one form or another. Even though the amount of TIM per vehicle may decrease, the overall emphasis on thermal management and the rapidly growing EV market will drive the demand for TIMs creating one of the largest potential markets. IDTechEx expects a 10-fold increase in the amount of TIM required for the EV industry in 2031 in comparison to 2020.

The new report from IDTechEx, “Thermal Interface Materials 2021-2031: Technologies, Markets and Opportunities”, considers the forms and compositions of TIMs, benchmarks commercial products, and details new advanced materials. It also analyzes current TIM applications in emerging markets as well as the key drivers and requirements in these areas such as electric vehicle batteries, data centers, LEDs, 4G & 5G infrastructure, smartphones, tablets and laptops. In addition, 10-year granular market forecasts are given for each of these segments in terms of application area and tonnage.