Rubber and elastomers make great seals—but did you know they can also provide corrosion protection? In many cases, gaskets, O-rings, and other rubber components exist in direct contact with metal, making them an ideal delivery system for corrosion inhibitors. Cortec Corporation outlines how these points of corrosion vulnerability can turn into agents of corrosion protection.

Corrosion Risk Factors Near Gaskets

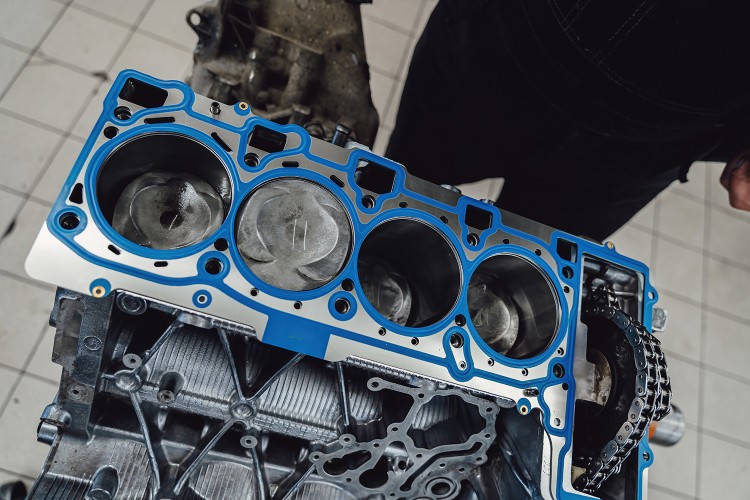

Many corrosion risks arise where rubber and metal meet. The sealing properties of gaskets inherently put them in frequent contact with water, which increases the risk of corrosion in pipe connections (e.g., flange faces), hose fittings, and boiler gaskets, to name a few examples. Corrosion in turn opens the door to leaking pipes and equipment, followed by costly repairs and downtime. To make matters worse, dissimilar metals may be used at these connecting points, introducing the risk of galvanic corrosion. In some cases, conductive gaskets used for shielding against electromagnetic or radio frequency interference (EMI or RFI) contain metal particles that could exacerbate the galvanic corrosion process. In short, gaskets often stand at an important crossroad of heightened corrosion risk.

Turning Seals into Shields

Located at such a strategic point, gaskets can also be a solution to the corrosion problem. By adding corrosion inhibitors to rubber or elastomer materials during compounding, manufacturers can deliver built-in corrosion protection to the metals in contact with the gasket or seal, thus reducing the risk for corrosion in the presence of dissimilar metals or simple moisture. M-138 is one corrosion inhibiting powder additive that can be compounded into nitrile, rubber, EPDM, and other elastomeric components. In favor of galvanic corrosion inhibition, M-138 protects multiple metals:

- Carbon steel

- Galvanized steel

- Aluminum

- Stainless steel

- Copper

- Brass

- Bronze

- Silver

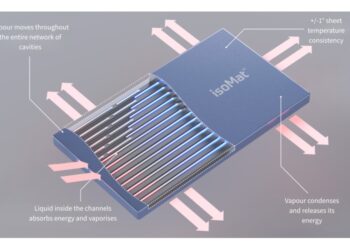

M-138 also contains Vapor phase Corrosion Inhibitors, turning treated elastomers into VpCI® emitting materials to protect metals enclosed in a cavity along with the treated elastomer (e.g., inside the rubber sleeve over an equipment joint). Potential applications are countless:

- Gaskets, O-rings, or seals in tools, strainers, gearboxes, boilers, and cooling towers

- Shielding gaskets for electronics

- Rubberized coatings

- Reinforced rubber hoses and belts

- Rubber sleeves covering equipment joints

Whether you are a gasket formulator or a manufacturer working with an elastomer supplier, thinking about adding corrosion protection to your rubbers and elastomers can be an important step toward building greater durability into the system you are designing. It also offers greater freedom for materials selection during the design phase.