“There are stair-step requirements to reduce nitrogen oxides and particulates in the commercial vehicle space and it is expected the off-highway segment will have to adhere to similar regulations in the near future,” said Craig Pytel, product manager, Vehicle Controls and Wireless, Eaton’s eMobility business. “Manufacturers are striving to electrify all aspects of vehicles and are in various stages of the technology curve. Eaton’s low-voltage products are rugged and able to withstand harsh environments, making them ideal for off-highway applications.”

The construction segment can convert to electrified vehicles, reduce emissions

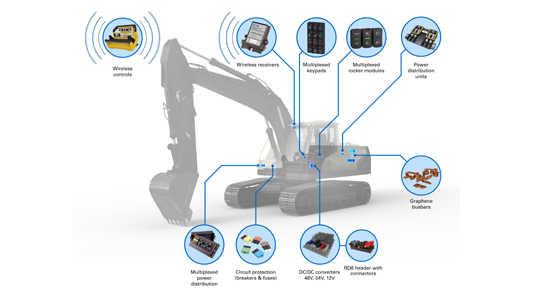

Eaton offers numerous low-voltage products for the construction field that allow critical vehicle component interaction, including control modules, “smart” switches and keypads, multiplex and controller area network (CAN)-based power distribution modules, traditional circuit breakers and fuses.

Construction equipment is sometimes necessary for indoor operations, necessitating an outside ventilation solution to prevent the harmful buildup of emissions. To simplify such operations, operators are looking for electrified versions of smaller equipment that can be operated safely indoors.

Construction equipment manufacturers are increasingly adopting higher-voltage architectures, including 48-volt and greater systems, to run more power-consuming equipment. While this fulfills power requirements, there is still a need to run traditional lower-voltage systems. Eaton’s DC-DC power conversion units can reduce or increase the voltage as needed. The units also maintain different voltage levels to prevent overloads or damage.

Agriculture industry converting to electrical components

Agriculture equipment manufacturers are following the lead of the commercial vehicle industry by replacing or augmenting existing equipment. Agricultural equipment is traditionally run by hydraulics, which today can be replaced with electrified components. This eliminates the risk of hydraulic leaks, which can contaminate soil and kill crops, and are expensive to repair.

48-volt electric catalyst heater controller provides precise aftertreatment control

Eaton’s air-cooled electric catalyst heater controller, part of its broader 48-volt electrical system portfolio, contains several technologies that allow manufacturers to integrate 48-volt architectures into next-generation vehicles. The controller manages power delivered to the aftertreatment heater and is designed to receive commands from the aftertreatment system and for maintaining system voltage control. The controller was developed to help manufacturers meet looming emissions regulations.

Eaton is an intelligent power management company dedicated to improving the quality of life and protecting the environment for people everywhere. We are guided by our commitment to do business right, to operate sustainably and to help our customers manage power ─ today and well into the future. By capitalizing on the global growth trends of electrification and digitalization, we’re accelerating the planet’s transition to renewable energy, helping to solve the world’s most urgent power management challenges, and doing what’s best for our stakeholders and all of society.