In the latest report, “Composite Materials for Green Energy Markets 2026-2046: Sustainable Technologies, Players & Trends”, IDTechEx provides a comprehensive analysis of the composite material innovations helping to address the growing waste crisis. The report assesses both emerging recyclable composite materials and recycling technologies, evaluates key players, and explores the roadmap for enabling circularity within the wind energy sector and beyond. Cumulative wind turbine blade waste is forecasted by IDTechEx to reach over 14 million tons by 2046, setting a clear precedent for driving sustainable material developments in the renewable energy space.

The Material Problem Behind Wind Energy Waste

Wind turbine blades are engineered for strength, lightweight design, and durability, typically fabricated using glass fiber reinforced thermosetting resins, such as epoxy. These materials deliver excellent mechanical properties but present a fundamental issue – they are extremely difficult to recycle. Thermosets contain irreversible covalent crosslinking between polymer chains, which require very high temperature or chemically aggressive methods for breakdown, processes which are both energy intensive and costly.

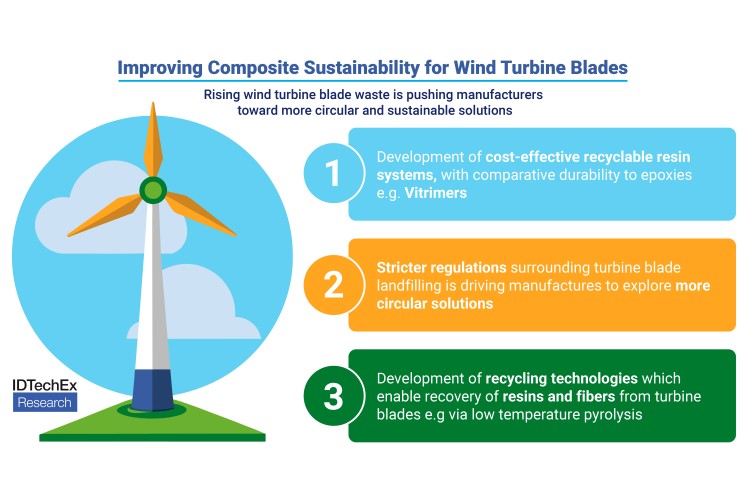

Currently, most decommissioned blades are either landfilled or mechanically downcycled into concrete fillers. These methods offer minimal value recovery and do not support a circular material economy. Mechanical recycling, although viable, remains limited in scale for turbine blades, and the reclaimed materials often suffer degradation, reducing properties and undermining economic feasibility. As environmental legislation tightens, such as landfill bans in Germany and the Netherlands, manufacturers are under growing pressure to find scalable, sustainable solutions.

The Rise of Recyclable Composites

To address these recycling barriers, the wind sector is pivoting toward advanced recyclable resin chemistries and more efficient end-of-life processes. In the latest report, IDTechEx identifies two main material innovation pathways helping to drive this shift:

1. Recyclable Thermosets

These include chemistries such as vitrimers or thermosets with cleavable bonds, which enable depolymerization or bond exchange for monomer recovery. Leading players such as Swancor, Aditya Birla, and Techstorm are all developing scalable resin systems that maintain the high performance of traditional epoxies while enabling post-use processability through processes such as solvolysis or pyrolysis.

2. Thermoplastics

Thermoplastics are inherently recyclable and are already well-understood in other industries. However, concerns over creep resistance, thermal stability, and long-term durability have so far restricted adoption in structural wind turbine applications. Even so, thermoplastics can offer cost and impact resistance advantages in future designs.

Despite technological advances, real-world deployment of recyclable resins faces several challenges. Manufacturers report cost premiums for these systems compared to conventional resins, often due to low production volumes and more complex raw material formulations. As well, the material complexity within blades, typically comprising multiple resin systems and protective coatings, reduces the effectiveness of a single recyclable solution. Unless the entire material system is designed for circularity, the individual resin recyclability benefits may be significantly diminished.

Several players highlighted to IDTechEx industry’s concerns regarding financial responsibility for blade recycling. With multiple stakeholders involved across a turbine’s lifecycle, EoL recyclers often face uncertain funding sources, further discouraging large-scale processing. Currently, most recycling efforts focus on recovering carbon fiber, which retains a higher value, while glass fiber, the more commonly used reinforcement, offers lower returns. This further exacerbates the waste management problem.

Legislative Momentum and Industry Response

Regulatory momentum is increasingly driving the wind sector toward circular material adoption. France, for example, since January 2024 has mandated all new wind turbine installations be 95% reusable and recyclable by mass. WindEurope continues to advocate for an EU-wide ban on blade landfilling by 2025. In response, some industry leaders are beginning to act. Siemens Gamesa has introduced the RecyclableBlade, utilizing Aditya Birla’s Recyclamine resin technology. Approximately 100 of these blades are currently in operation, representing one of the first commercial deployments of recyclable blade systems. Commencing in 2026, Swancor is also set to supply its recyclable resin “EzCiclo” to Siemens Gamesa, helping to strengthen the RecyclableBlade production capacity.

Looking Ahead: Composite Innovation for a Sustainable Wind Energy Sector

Wind energy is set to remain a dominant force in the global clean energy mix. However, without significant improvements in material sustainability, the sector risks undermining its environmental and financial foundations. The development and scale-up of recyclable composite systems, capable of recovery, reuse, and redeployment, will be critical to ensuring long-term viability.

With detailed profiles of key material developers, analysis of thermal, chemical and mechanical recycling technologies, and twenty-year market forecasts, IDTechEx’s report “Composite Materials for Green Energy Markets 2026-2046: Sustainable Technologies, Players & Trends” serves as a comprehensive roadmap navigating the shift toward sustainable composite use in green energy applications.

For more information on this report, including downloadable sample pages, please visit www.IDTechEx.com/Composite, or for the full portfolio of research, visit www.IDTechEx.com.