NORTHBROOK – UL Solutions has announced the Battery Enclosure Thermal Runaway (BETR) evaluation, the first material screening test method at UL Solutions to evaluate electric vehicle (EV) battery enclosure material. The offering based on UL 2596, Test Method for Thermal and Mechanical Performance of Battery Enclosure Materials, was published on Jan. 27, 2022, by the UL Standards and Engagement organization.

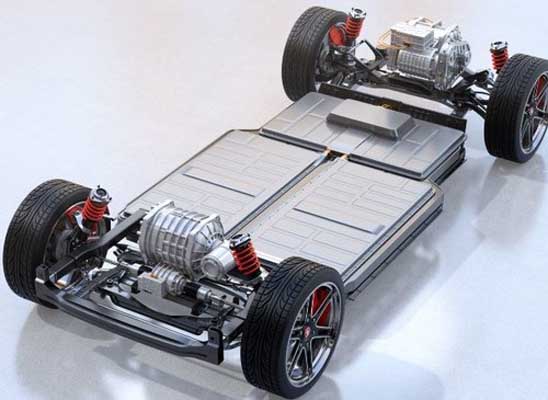

Battery performance has continually presented challenges in EV efficiency, as the heavier weight of EVs — caused by heavy battery systems — means more frequent charging and shorter drive times. However, battery enclosure systems play a critical role in mitigating the impact of thermal runaway, a risk associated with lithium-ion batteries. Thermal runaway occurs when the lithium-ion cell enters an uncontrollable self-heating state that can produce fire, smoke and extremely high temperatures while ejecting harmful particulates.

“As the electrification of mobility continues to grow, thermal runaway has become a critical safety issue in the automotive industry and has heightened attention concerning how optimal enclosure material is used for thermal runaway protection,” said Eric Bulington, director of product management in the Engineered Materials group of UL Solutions. “With this offering, we are helping manufacturers navigate one of the e-Mobility industry’s most complex challenges while meeting the market demand for innovative and trustworthy automotive products.”

The UL Solutions testing methodology evaluates material performance by simulating a thermal runaway scenario. The evaluations entail testing material plaques versus the entire battery assembly, reducing testing costs and development time for resin manufacturers and material suppliers. Evaluations also focus on screening multiple formulas during research and development to provide material producers the opportunity to offer original equipment manufacturers (OEMs) the solutions that meet their needs while also considering performance among materials.

“UL Solutions has a long history of thought leadership with respect to batteries of all shapes and sizes, so it’s fitting that we continue that legacy with EV batteries,” Bulington said. “With this offering, UL Solutions addresses industry concerns by providing automotive OEMs and suppliers, and automotive component and system manufacturers, testing and advisory solutions to meet multiple standards and regulations.”