TORONTO, Sept. 23, 2020– Inmotive, a Canadian-based automotive supplier, has launched its patented IngearTM two-speed transmission. Invented and designed for the next generation of electric vehicles, the Ingear features a simple and durable design that enables a more efficient powertrain, with extended range, at lower cost.

Inmotive recently completed its extensive pre-production testing of the Ingear, has integrated it into a demonstration vehicle and is ready for full market implementation. Test units are available to qualified OEMs.

“This next-generation transmission offers an entirely new way of looking at multi-speed transmissions for electric vehicles and extends significant benefits to a wide range of other market segments as well,” said Paul Bottero, CEO, Inmotive. “It is the first two-speed transmission of its kind to be effectively ready for global market adoption.”

How it works

Currently, most EVs use single-speed transmissions, however, equipping an EV with an Ingear transmission lowers cost, extends range and improves acceleration times, highway passing capability, top-speed and gradeability.

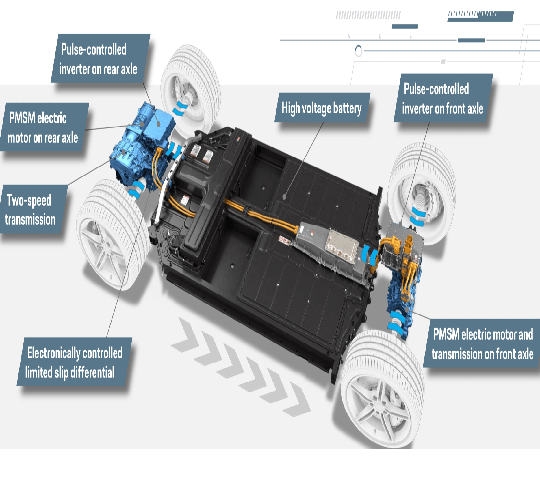

Typically, there are two reduction gears between the electric motor and the wheels, with the motor turning about nine times for each revolution of the wheels. The Ingear replaces the second reduction gear with a continuous chain drive and a morphing sprocket. To shift, an actuator directs sprocket segments into place during a single revolution of the wheels, effectively increasing or decreasing the gear ratio. The Ingear’s patented geometry keeps the motor and wheels in sync, enabling continuous torque flow throughout the shift process.

By enabling the drivetrain to operate more efficiently with low and high-gear ability, less energy is wasted resulting in more range from each charge. Similarly, regeneration is improved and is continuous, even while downshifting.

“We’ve found that today’s automatic transmissions fall short of what the EV industry needs,” said Bottero. “With an efficient design and substantial cost savings to the OEM, we believe the Ingear transmission checks all of the boxes that OEMs have been looking for and will help support wide-spread adoption of EVs.”

Delivering ultimate performance

Key benefits of the new Ingear transmission include:

- Cost Saving – By integrating the simple and low-component-count Ingear into high volume integrated drive units, OEMs can save more than $1,500 per passenger vehicle. This savings is possible through using less battery and less expensive electric motors and inverters all while maintaining the same range and improving acceleration. In addition to OEM savings, fleet owners will save about $2,000 in operating (electricity) costs over three years.

- Compact – Designed to wrap around the differential, the Ingear is only slightly larger than a typical single speed transmission.

- Quick, smooth and quiet – The Ingear shifts in less than a single revolution of the wheels. The motor is kept in constant contact with the wheels and can continuously apply torque even during the shift. Gear ratios change gradually and torque fill algorithms maintain a smooth passenger experience. Acceleration times can be improved by up to 15%.

- Efficient and reliable – The Ingear extends the range of a typical vehicle by up to 15% by optimizing motor efficiency and reducing parasitic losses. It also improves towing, hill-climbing and top-speed.

Technology adoption

Ingear is not a “one size fits all” technology. Its design flexibility enables OEMs to customize the size and scale of the technology based on the specific vehicle type. While initial development has focused on the passenger car market, the technology can be adapted for a wide range of vehicles, including commercial, off-highway and fuel cell applications.

Inmotive currently has development contracts with two global OEMs and is in discussion with several other OEMs from around the world for implementation.