The global waterjet cutting machine market size is set to account for a valuation of US$ 44.58 billion in 2024 and is forecasted to reach US$ 74.01 billion by the end of 2034. Worldwide demand for waterjet cutting machines is forecasted to rise at 5.2% CAGR over the next 10 years (2024 to 2034).

The waterjet cutting machine market has experienced significant growth in recent years, driven by advancements in technology, expanding applications across various industries, and increasing demand for precision cutting solutions. Waterjet cutting technology utilizes high-pressure water mixed with abrasives to cut through materials ranging from metals to composites, ceramics, and even stone, offering several advantages over traditional cutting methods like laser or plasma cutting.

Market Overview and Growth Factors

The global waterjet cutting machine market has been expanding due to several key factors:

1. Diverse Industrial Applications: Waterjet cutting machines are widely used across industries such as automotive, aerospace, manufacturing, construction, and electronics. They are valued for their ability to cut intricate shapes with high precision without heat-affected zones, which is crucial for sensitive materials.

2. Growing Demand for Precision Cutting: As industries demand higher precision in manufacturing processes, waterjet cutting machines have emerged as a preferred choice. They offer excellent accuracy and can handle a wide range of materials and thicknesses, making them versatile in various production environments.

3. Advancements in Technology: Continuous technological advancements have enhanced the capabilities of waterjet cutting machines. Innovations include faster cutting speeds, improved control systems for higher accuracy, and integration with CAD/CAM software for seamless operation.

4. Environmental Sustainability: Compared to traditional cutting methods, waterjet cutting is considered environmentally friendly. It produces minimal waste, as the water and abrasive materials used can often be recycled. This aspect has become increasingly important with the growing focus on sustainable manufacturing practices.

5. Rise in Automation: Automation trends in manufacturing have also influenced the waterjet cutting machine market. Automated systems reduce labor costs, improve efficiency, and enable continuous operation, further driving market growth.

Market Segmentation

The waterjet cutting machine market can be segmented based on technology type, product type, pressure range, application, and geography:

- By Technology Type: Abrasive waterjet cutting and pure waterjet cutting.

- By Product Type: 3-axis, 5-axis, and micro waterjet cutting machines.

- By Pressure Range: Low pressure (below 420 MPa) and high pressure (above 420 MPa).

- By Application: Automotive, aerospace, electronics, ceramics, food processing, and others.

Regional Insights

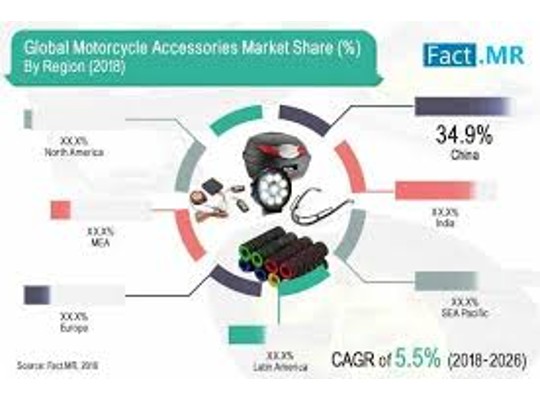

Geographically, North America and Europe have traditionally been key markets for waterjet cutting machines due to established manufacturing sectors and high adoption rates of advanced technologies. Asia-Pacific is emerging as a significant market, driven by rapid industrialization in countries like China and India, coupled with increasing investments in manufacturing infrastructure.

Competitive Landscape

The waterjet cutting machine market is competitive, with several key players dominating the global landscape. Major companies invest heavily in research and development to introduce innovative products and expand their market presence. Some of the prominent players include Flow International Corporation, OMAX Corporation, DARDI International Corporation, and Jet Edge Inc.

Challenges and Future Outlook

Despite its advantages, the waterjet cutting machine market faces challenges such as high initial costs, especially for advanced models, and the need for skilled operators. However, ongoing technological advancements and increasing automation are expected to address these challenges, driving further market expansion.

Looking ahead, the waterjet cutting machine market is poised for continued growth, supported by the demand for precision cutting solutions across diverse industries. As manufacturing processes evolve towards higher efficiency and sustainability, waterjet cutting technology is likely to play a pivotal role in shaping the future of industrial production worldwide.