IDTechEx explores the growth of sustainable composites for green energy applications

Composite materials have long been celebrated for their unique blend of strength, lightweight design, and corrosion resistance. From aerospace and automotive to construction and renewable energy, fiber reinforced polymers (FRPs), particularly glass fiber reinforced (GFRP) and carbon fiber reinforced (CFRP) systems, are at the center of modern engineering. They enable longer wind turbine blades, lighter electric vehicles, and stronger hydrogen storage vessels, technologies that are fundamental to decarbonization and the global energy transition.

Yet, as the adoption of composites accelerates, so too does the scrutiny of their environmental impact. Most end-of-life (EoL) composites are landfilled or incinerated, contributing to a looming waste crisis. With regulatory pressures mounting, the industry is turning its attention to more sustainable and recyclable resin systems as a critical step toward material circularity.

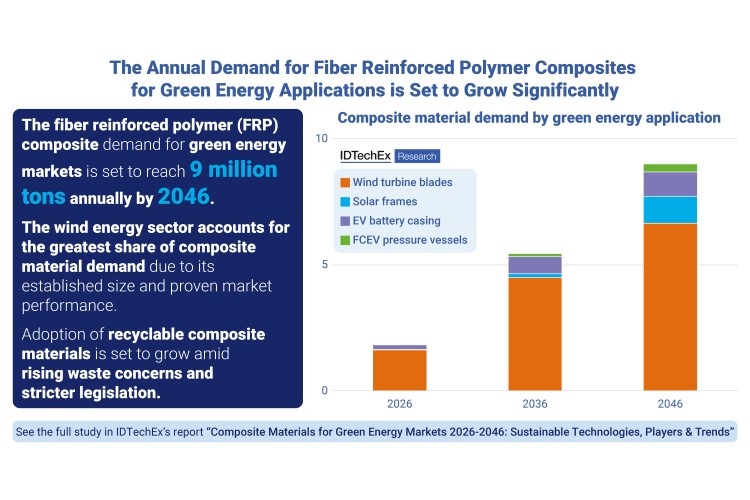

In a recent report “Composite Materials for Green Energy Markets 2026–2046: Sustainable Technologies, Players & Trends”, IDTechEx explores the innovations enabling composite circularity. The report analyzes regulatory drivers, emerging resin chemistries, recycling techniques, and bio-based alternatives. Detailed market assessments provide granular 20-year forecasts for the green energy sector, covering applications in wind energy, hydrogen, electric vehicles and solar energy.

IDTechEx predicts that composite demand in green energy applications alone will reach 9 million tons annually by 2046, underlining both the scale of the opportunity and the urgency of addressing sustainability challenges.

Why Recycling Composites is a Challenge

The difficulty of recycling composites is rooted in their fundamental design. FRPs typically use thermoset resins as the matrix material. These resins form covalent crosslinks between chains during curing, creating excellent mechanical and chemical stability but preventing remelting or recycling. Breaking these bonds requires extreme heat or aggressive chemicals, making recovery both energy-intensive and costly. As a result, most waste is either landfilled or mechanically downcycled into low-value fillers, with significant performance losses.

The challenge is compounded by the long service life of composites. Wind turbine blades, for example, are designed to last 25 years or more. Many of the first large-scale wind farms commissioned in the 1990s and early 2000s are now approaching decommissioning, bringing with them significant waste volumes.

Adding to this complexity is the heterogeneous structure of composites, typically combining resins, fiber blends, foams, adhesives, primers, and coatings, all of which complicate downstream separation and recycling.

Another significant barrier is the lack of material traceability. Few composite products are manufactured with detailed product passports, leaving end-users without clear material composition to select suitable recycling pathways. Repairs, modifications, and long operational exposure further obscure material composition, limiting recyclers’ ability to recover high-value materials.

Emerging Solutions: Recyclable Resin Systems

To address these challenges, material developers are advancing new resin chemistries designed for recyclability. These fall broadly into two categories: thermoplastics and recyclable thermosets.

Thermoplastics

Thermoplastic resins such as polypropylene (PP), nylon, PET, and high-performance polymers like PEEK are inherently recyclable, softening when heated and allowing for reuse. Their relative toughness and impact resistance make them attractive for certain applications, and companies like Arkema have developed thermoplastics for composite use. However, limitations in chemical and thermal resistance, along with susceptibility to creep, have restricted uptake in demanding structural sectors such as wind energy.

Recyclable Thermosets

Recyclable thermosets are an emerging class of materials that aim to combine the durability of thermosets with the reprocessability of thermoplastics. By introducing dynamic or cleavable bonds, these systems can undergo depolymerization or bond exchange under controlled conditions, enabling recycling without sacrificing performance.

Vitrimers are one of the most promising examples, offering thermoset-like mechanical strength while allowing reprocessing through dynamic covalent equilibrium. Companies such as Westlake Epoxy and Techstorm are developing vitrimer-based systems, particularly targeted at wind turbine blade applications.

Other recyclable thermosets rely on cleavable bond chemistries. Swancor’s EzCiclo resin and Aditya Birla’s Recyclamine have already seen commercial adoption, offering drop-in compatibility with existing manufacturing processes. Challenges remain, however, recycling may downgrade materials from thermosets to thermoplastics, reducing their recovered value and limiting reuse in high-performance applications.

Recycling Pathways

Development of resin chemistries must be matched by progress in recycling techniques to ensure high-value material recovery with minimal environmental impact. There are three main recycling pathways explored by industry:

- Mechanical recycling is simple and relatively low-energy but typically results in fiber degradation and downcycling into low-value applications.

- Thermal recycling is more established, with techniques such as pyrolysis enabling fiber recovery and, in some cases, resin reuse. Low-temperature pyrolysis is emerging as a promising route to minimize degradation, though energy intensity overall remains a drawback.

- Chemical recycling is perhaps the most promising, using milder conditions to recover both fibers and resins with limited damage. Though commercialization is still limited, companies such as Techstorm and Vartega are developing solvolysis-based processes capable of producing high-quality recycled fibers for direct application reuse.

Opportunities and Outlook

Recyclable thermoset resin technologies remain in the relatively early stages of commercialization, with cost premiums and qualification hurdles slowing widespread adoption. However, regulatory and market dynamics are shifting the outlook. Landfill bans for wind turbine blades in Europe, combined with tightening waste regulations globally, are creating powerful incentives for sustainable material innovation. For resin developers, this presents a significant market opportunity. As renewable energy infrastructure expands, the demand for lightweight, high-performance, and recyclable composites will only grow.

With detailed profiles of key players, comparative analysis of resin chemistries, and 20-year forecasts, IDTechEx’s latest report, “Composite Materials for Green Energy Markets 2026–2046: Sustainable Technologies, Players & Trends”, provides a roadmap for navigating this transition and unlocking the potential of sustainable composites in the green energy era.

For more information on this report, including downloadable sample pages, please visit www.IDTechEx.com/Composites, or for the full portfolio of sustainability and materials-related research available from IDTechEx, see www.IDTechEx.com.