HOUSTON – Lummus Technology announced the start-up of its CDAlky alkylation unit at Zhejiang Petroleum & Chemical Co. Ltd.’s (ZPC) refinery in Zhejiang Province, China. The unit has a capacity of 45,000 BPSD of alkylate product, making it the largest alkylation unit ever licensed by Lummus.

“The successful start-up for ZPC, plus the one we announced recently for Valero, underscore the best-in-class technology solutions we offer to major operators all over the world,” said Leon de Bruyn, President and Chief Executive Officer of Lummus Technology. “Given the unit’s unique and advanced features, such as the scale and the nature of the feedstock, this achievement reflects Lummus’ ability to adapt, innovate and collaborate closely with our customers.”

The start-up is the second Lummus CDAlky unit at ZPC’s complex for a combined capacity of 59,000 BPSD of alkylate production, making it the second largest alkylation complex in the world.

The new alkylation unit processes C4s from upstream refining and petrochemical units, resulting in a very high concentration of isobutylene in the total olefins blend while producing a superior alkylate quality.

Earlier this year, Lummus announced the successful start-up of the first C5 CDAlky unit in the world, and Lummus’ first CDAlky unit in the U.S, located at Valero’s Saint Charles Refinery in Norco, Louisiana. The ZPC and Valero start-ups demonstrate CDAlky‘s flexibility to process olefins from different sources and to produce premium alkylate with lower capital and operating costs.

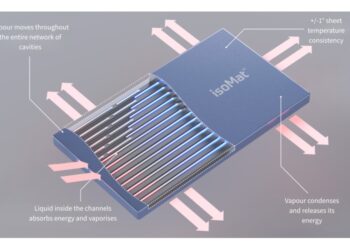

Lummus’ CDAlky technology is an advanced low-temperature sulfuric acid alkylation process for the production of premium motor fuel alkylate. It reacts light olefin streams from refinery sources such as fluid catalytic cracking units or from steam cracking units with iso-paraffins to produce fuel alkylate. Central to the CDAlky process is a novel reaction system design that improves mass transfer compared to conventional contactors. The CDAlky process is available for license to the petroleum refining and petrochemical industries.